[最も共有された! √] yield stress ratio formula 174425-Yield stress ratio formula

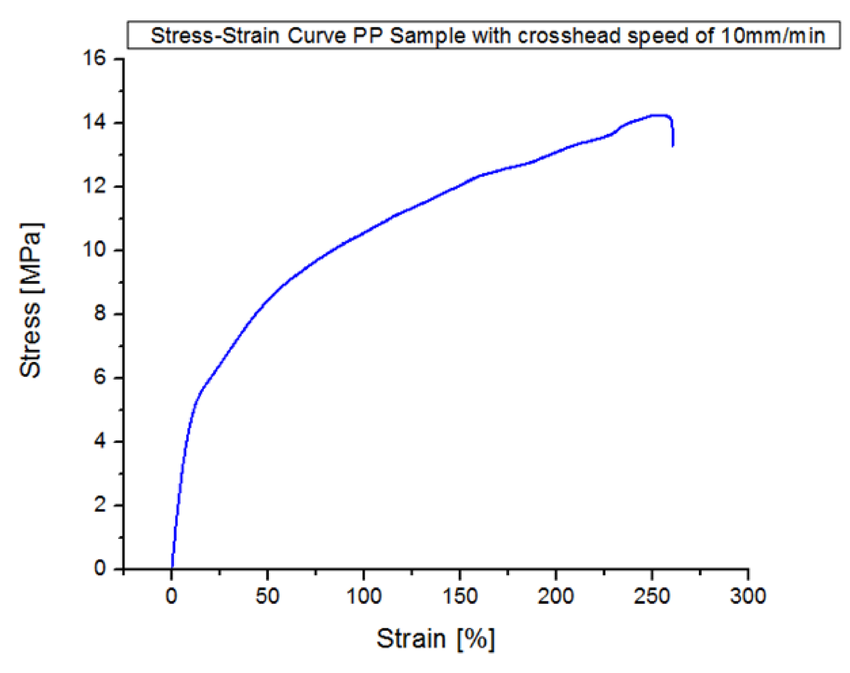

The elastic modulus obtained from the stress–strain curves and the average strain rate calculated from the measured strain–time curve before failure occurs are shown in Table 118With the existence of dynamic loads and initial static loads, the dynamic and static elastic modulus and Poisson's ratio refer to the corresponding value under dynamic and static conditionsDislocations which in turn governs the yield stress Consequently, the Y/T ratio is higher for modern steels The typical relationships between yield strength and Y/T ratio are shown in Fig 3 from different sources(3,4) Since a low Y/T ratio has formerly been considered as providing a high capacity for strain hardening, and a safe margin againstPoisson's Ratio Definition When a deforming force is applied at the free end of a suspended wire of length l and radius R, then its length increases by dl but its radius decreases by dR Now two types of strains are produced by a single force

Q Tbn And9gcqdhkmo7hherjjmwerev9j1zxqfwpmjetj5gvnkildcbtyau41x Usqp Cau

Yield stress ratio formula

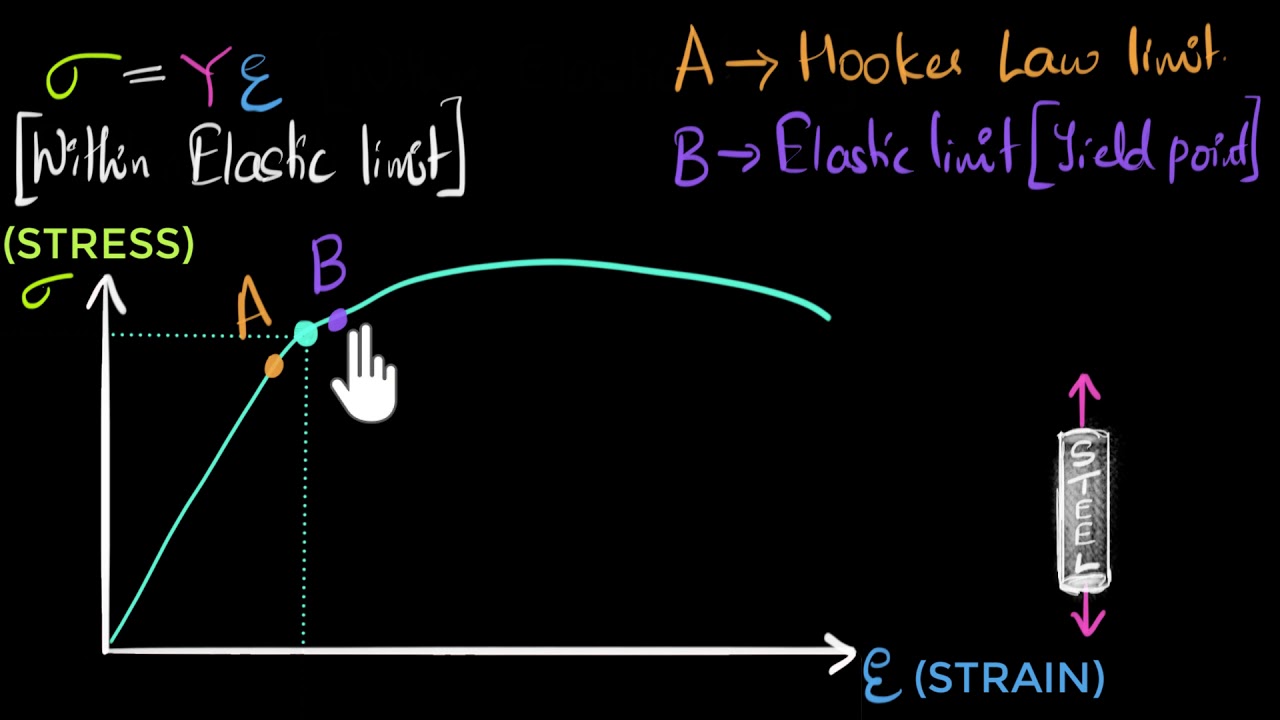

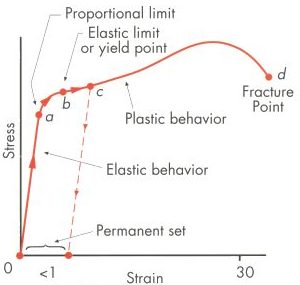

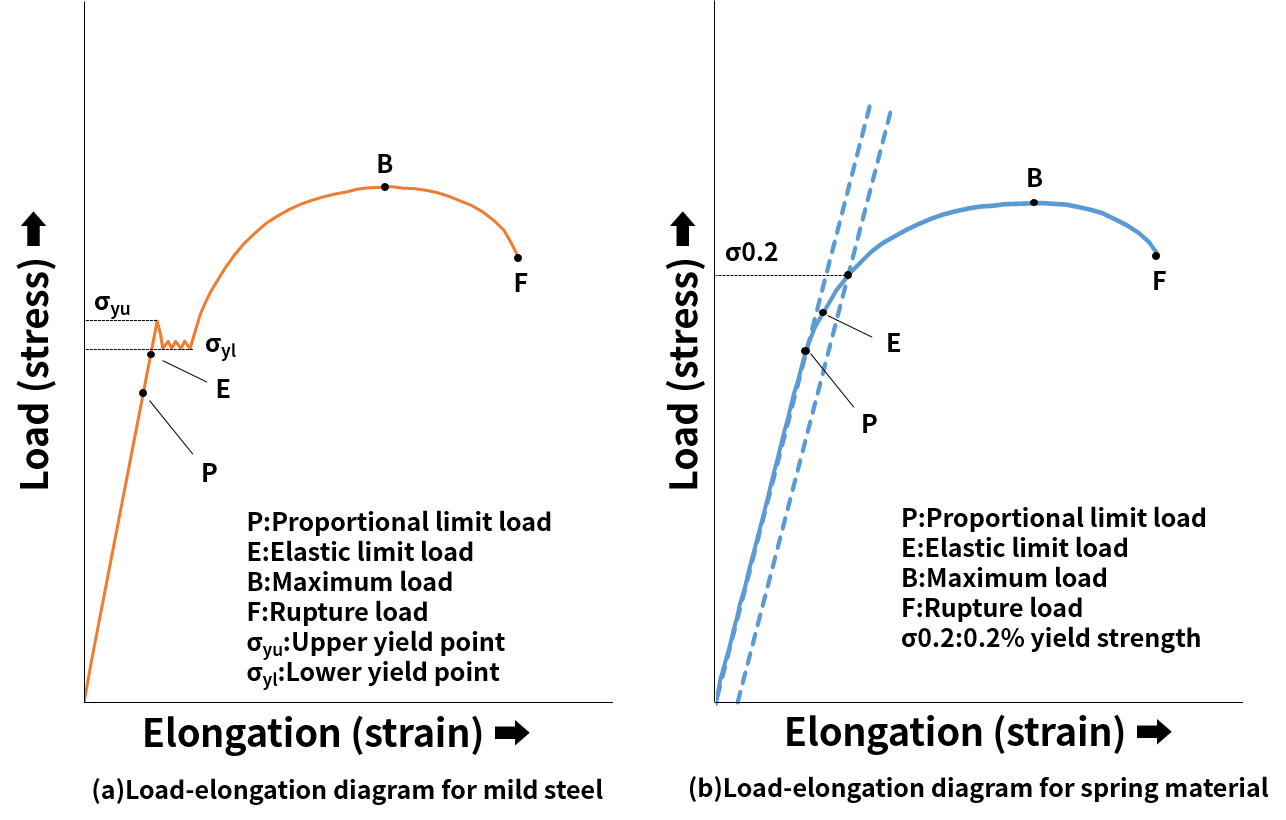

Yield stress ratio formula-The yield point happens after an object has reached its yield stress This example is of steel Steel materials have a yield point, which causes them to have a large horizontal portion of the graphThat exhibit distinct yield behavior, the intercept of the line through the stress axis represents a yield stress Comparing the yield stresses for our two sealants we have 170 Pa for sample 1 and 510 Pa for sample 2 It is now a simple matter to set a maximum permissible yield stress for quality control purposes

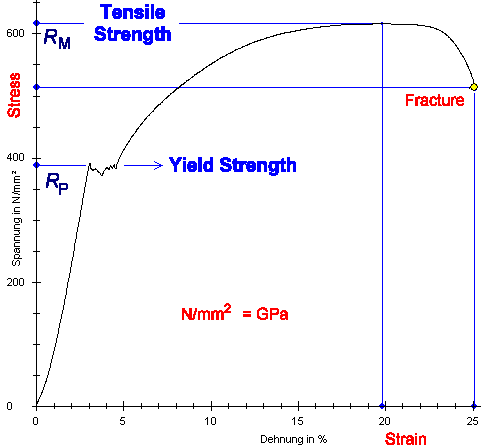

Stress Strain

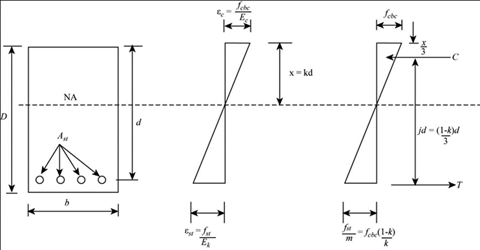

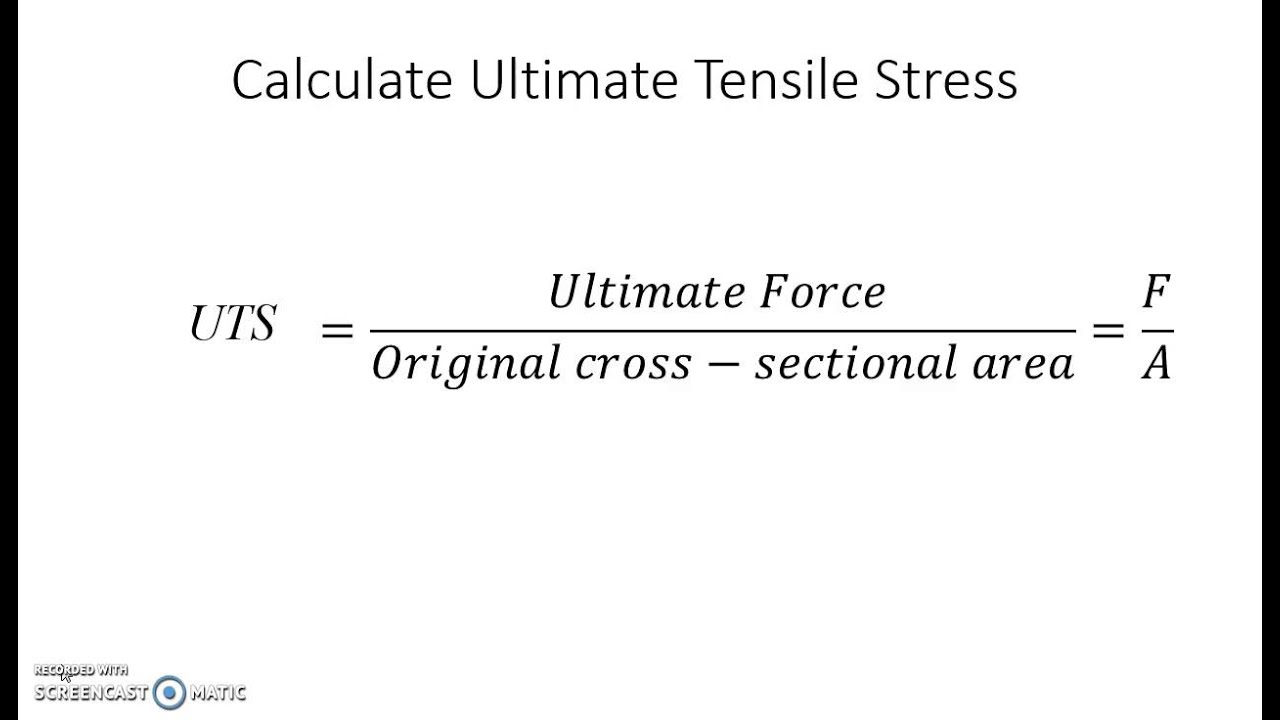

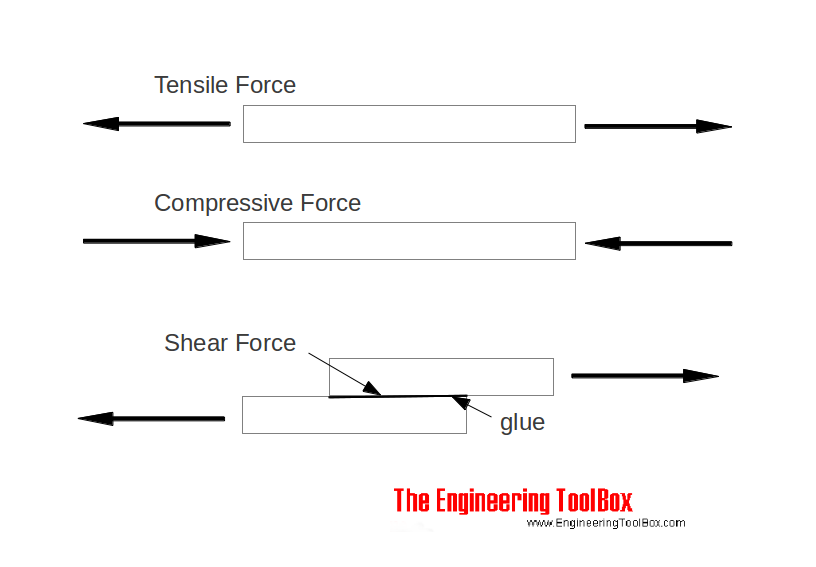

Stress Stress is the ratio of applied force F to a cross section areadefined as "force per unit area" tensile stress stress that tends to stretch or lengthen the material acts normal to the stressed area;The Shear strength of a material under pure shear is usually 1/√3 (0577) times its tensile yield strength in case of Von mises criterion and 05 times its tensile yield strength in case ofC = compression in concrete = stress x area = 085 f´cba T = tension in steel = stress x area = A s f y C = T and Mn = T(da/2) where f' c = concrete compression strength a = height of stress block b = width of stress block f y = steel yield strength A s = area of steel reinforcement d = effective depth of section (depth to na of reinforcement)

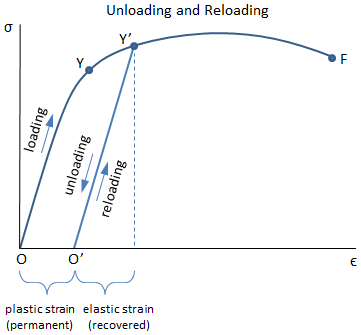

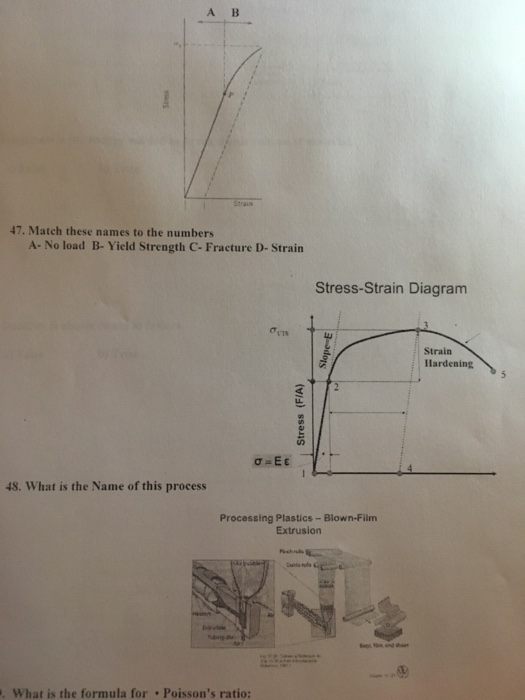

FORMULA F FORCE SECTION AREA = STRESS= A F FORCE SECTION AREA = STRESS= A CHANGE IN LENGTH ORIGINAL LENGTH STRAIN ( ) = FORMULA The sample metal (above) being tested, is 0mm in length when no force is applied (no load) However, when force / a load is applied it stretches to a length of 210mmSo by applying the abovegiven formula Yield Ratio of the screening process = (42 / 185) x 100% = 2277 % = 23 % This numbers will go on increasing as you move up in stages until the final recruitment Benefits of Yield Ratio Yield ratio is one of the important KPI (Key Performance Indicator) in human resourcesIn materials science and engineering, the yield point is the point on a stressstrain curve that indicates the limit of elastic behavior and the beginning of plastic behavior Below the yield point, a material will deform elastically and will return to its original shape when the applied stress is removed Once the yield point is passed, some fraction of the deformation will be permanent and

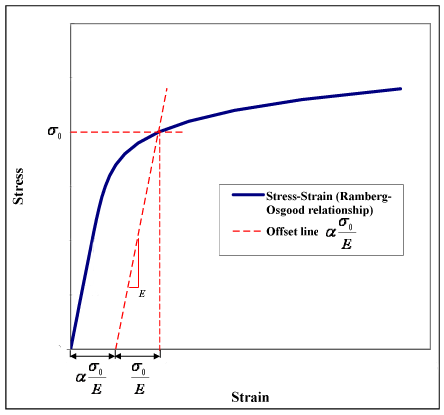

The working stress or allowable stress is the maximum safe stress a material may carry The working stress should not exceed proportional limit Since the proportional limit is difficult to determine accurately, we take yield point or the ultimate strength and divide this stress by a suitable number N, called the factor of safetyThe most common engineering approximation for yield stress is the 02 percent offset rule To apply this rule, assume that yield strain is 02 percent, and multiply by Young's Modulus for your material σ = 0 0 0 2 × E \sigma = 0002\times E σ = 0002×EDiameter / thickness ratio and the yield strength of the pipe Axial strength of the pipe body is calculated from the formula below Fy = (π/4) * (D2 – d2) Yp Fy = tension strength (lbs rounded to the nearest 1,000) Yp = yield strength of pipe ( psi) D = OD of pipe (inches) d = ID of pipe (inches)

Formulas For Yield Stress

Q Tbn And9gcq6zmctjndkkjpyak Xrcdf5heom0h Yhbhe5u3bt9reft0h3if Usqp Cau

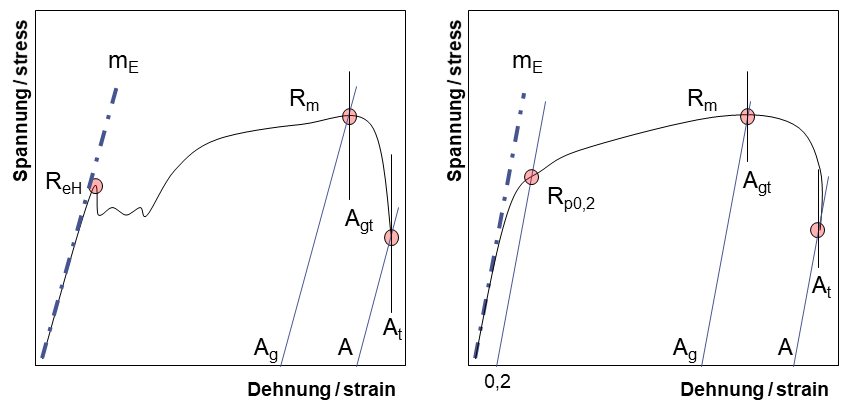

Yield Strength Definition Stress Strain Graph Stress Strain Graph Explanation Yield Strength Graph What is Yield Strength?YIELD STRESS/TENSILE STRESS RATIO RESULTS OF EXPERIMENTAL PROGRAMME British Steel plc 1 INTRODUCTION 11 Concepts of the Yield/Tensile Ratio One of the principal objectives of many modern steel structures is the optimisation of the useful weight by providing an efficient design incorporating high strength steelsYield point is a point on the stressstrain curve at which there is a sudden increase in strain without a corresponding increase in stress Not all materials have a yield point See accompanying figure at (1) Yield strength, S y, is the maximum stress that can be applied without permanent deformation of the test specimen This is the value of

Science Of Uniaxial Deformation

Strength At Break Tensile

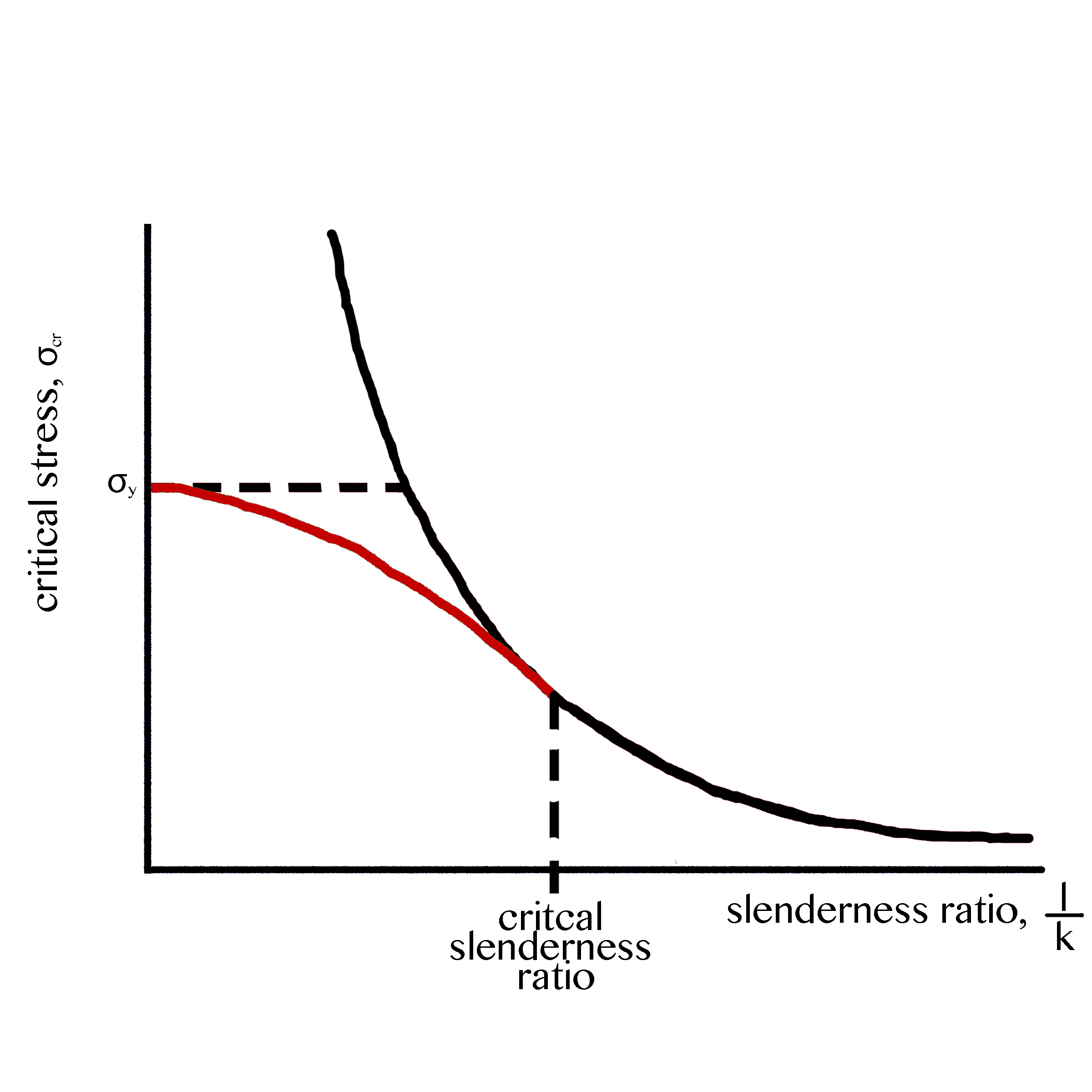

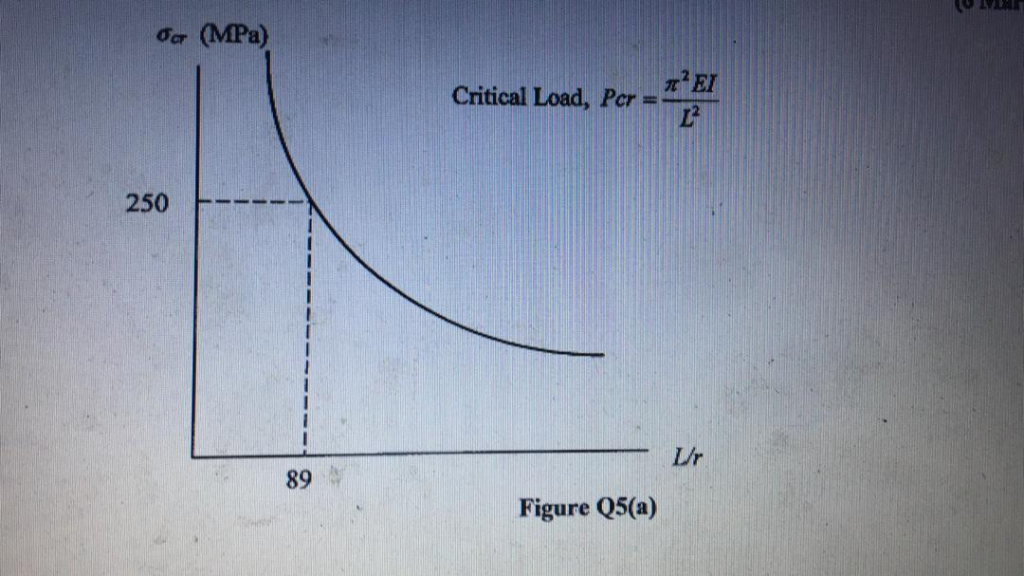

Yield stress is defined as the stress after which material extension takes place more quickly with no or little increase in load Point (BC) is the yield point on the graph and stress associated with this point is known as yield stress Ultimate Stress Point (D) Ultimate stress point is the maximum strength that material has to bear stressFig 1 Critical stress vs slenderness ratio for steel, for E = 0 GPa, yield strength = 240 MPa Euler's critical load is the compressive load at which a slender column will suddenly bend or buckle It is given by the formula P c r = π 2 E I ( K L ) 2 {\displaystyle P_ {cr}= {\frac {\pi ^ {2}EI} { (KL)^ {2}}}} whereYield Stress Equation Yield stress = F/ A Where, F = Force at yield A = Orginal Cross Section area Yield stress formula is quite simple Divide the yield force and original crosssectional area to find yield stress Make use of the yield stress equation to find the point where the material elasticity ends

Solved The Strength To Weight Ratio Of A Structural Material I Chegg Com

The Strain Rate Effect Of Engineering Materials And Its Unified Model

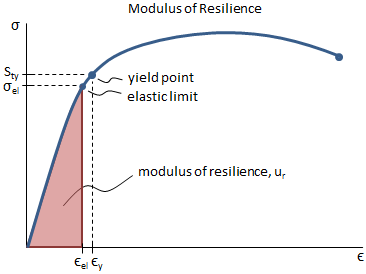

That exhibit distinct yield behavior, the intercept of the line through the stress axis represents a yield stress Comparing the yield stresses for our two sealants we have 170 Pa for sample 1 and 510 Pa for sample 2 It is now a simple matter to set a maximum permissible yield stress for quality control purposesUnit Conversion Calculator & Converter for Tensile/Yield & Charpy values Use the following calculator to convert yield or tensile values in ksi, Mpa, N/mm² or psi Type the value in the box next to Mpa (using the drop down to change the unit of measurement)Modulus of resilience It is defined as the ratio between tensile stress and two times the Youngs modulus of the material Fracture stress It is defined as the maximum stress that is experienced in a crack point before it breaks down and is denoted as σ f Tensile Stress Formula

.jpg)

Yield Stress Calculation Methods

Yield Strength Strength Mechanics Of Materials Engineers Edge

Definition There are two definitions for the factor of safety (FoS) The ratio of a structure's absolute strength (structural capability) to actual applied load;Material 24T4 Aluminum, Yield Strength= psi, Modulus of Elasticity=104E6 psi, Poisson's Ratio=333 Max Bending Stress o V H W t = 393 lbf o K o = 125 Overload Factor, based on light shocks encountered o K v = 110 Dynamic Factor, based on quality and velocity of gears o K s = 1 Size Factor o PFactor of safety (FoS), also known as safety factor (SF), is a term describing the structural capacity of a system beyond the expected loads or actual loadsEssentially, how much stronger the system is than it usually needs to be for an intended load Safety factors are often calculated using detailed analysis because comprehensive testing is impractical on many projects, such as bridges and

Correlation Between Engineering Stress Strain And True Stress Strain Curve

.jpg)

Yield Stress Calculation Methods

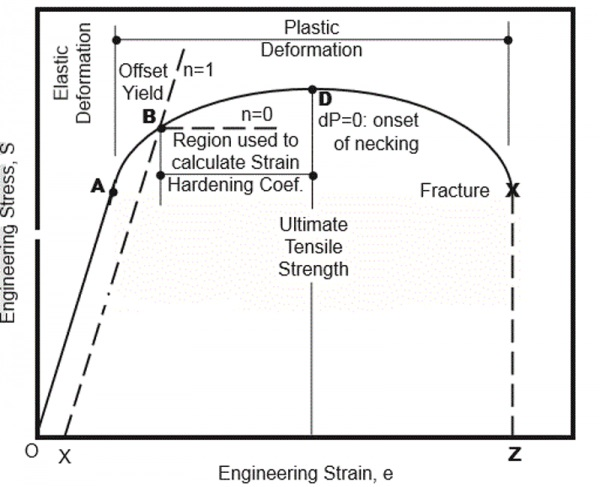

Compressive stress stress that tends to compress or shorten the material acts normal to the stressed area;The equation interpolates between the yield stress of the material to the critical buckling stress given by Euler's formula relating the slenderness ratio to the stress required to buckle a column Buckling refers to a mode of failure in which the structure loses stability It is caused by a lack of structural stiffnessOffset Yield Strength This is a somewhat arbitrary point Common values are 01% and 02% This point is well within the plastic region To use your method, you'll need the strain for the Proportionality Limit For example, A36 steel has a yield strength of 250 MPa, and an elongation at break of %

What Is Yield Stress Definition Formula Video Lesson Transcript Study Com

113 Questions With Answers In Yield Strength Science Topic

Definition There are two definitions for the factor of safety (FoS) The ratio of a structure's absolute strength (structural capability) to actual applied load;Define yield stress ratios to specify the rate dependence independently, as described in the procedure below For more information on strain rate dependence, see Ratedependent yield Create a material model as described in described in one of the following sectionsWhen the stress in a specific position becomes superior to the strength of the material, the safety factor ratio becomes inferior to 1, this when there is danger What it tells us basically is that in a specific area of the model, the stress is higher than the strength the material can bear

Q Tbn And9gcrdlwvzddnehsqd3q4pa68yhsrtz2zujhc4jj P3hg9jteevyia Usqp Cau

Which Methods To Use For Sheet Metal Tension Testing

Whether an object is stubborn or malleable is decided by the yield strength It is the point at which an object ceases to be elastic and becomes plastic Yield strength helps us choose appropriate materials for the construction based on the requirementYield ratios can give you an indepth picture of your hiring process when they're analyzed according to certain criteria For example, imagine that you calculate the gender ratio for new hires You find that percent of your total new hires are women You could perform the same kind of calculation for minoritiesThis is a measure of the reliability of a particular design This is a calculated value, and is sometimes referred to, for the sake of clarity, as a realized factor of safety;

Exploring The Stress Strain Curve For Mild Steel The Chicago Curve

What Is The Relationship Between Ultimate Tensile Strength Young Modulus And Elongation At Break

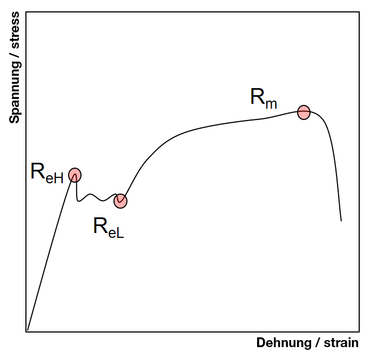

Factor of safety (FoS), also known as safety factor (SF), is a term describing the structural capacity of a system beyond the expected loads or actual loadsEssentially, how much stronger the system is than it usually needs to be for an intended load Safety factors are often calculated using detailed analysis because comprehensive testing is impractical on many projects, such as bridges andThis is a measure of the reliability of a particular design This is a calculated value, and is sometimes referred to, for the sake of clarity, as a realized factor of safety;YP ⇒ Yield Point Stress at which there are large increases in strain with little or no increase in stress Among common structural materials, only steel exhibits this type of response σ YS ⇒ Yield Strength The maximum stress that can be applied without exceeding a specified value of permanent strain (typically 2% = 002 in/in)

What Is Yield Stress Definition Formula Video Lesson Transcript Study Com

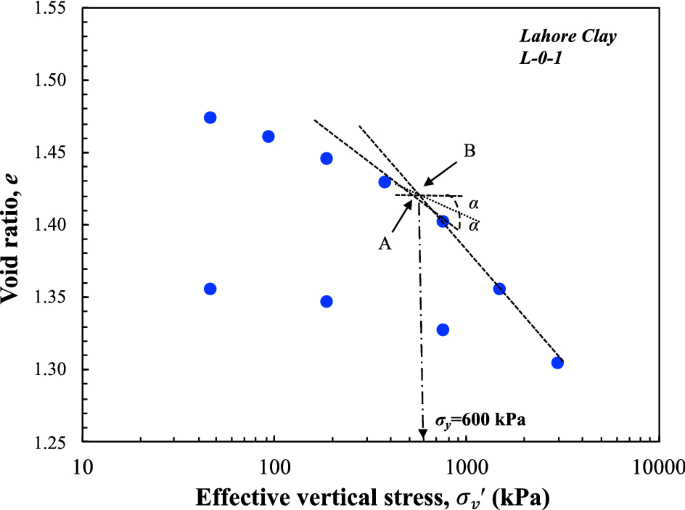

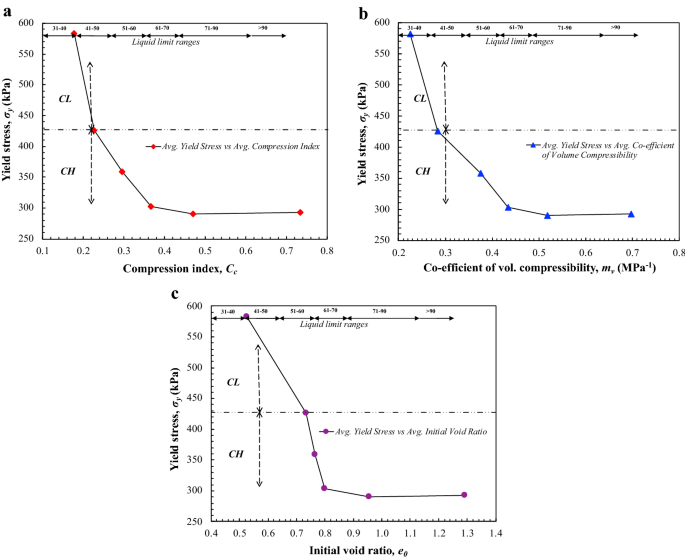

On Yield Stress Of Compacted Clays Springerlink

= allowable shear strength V n = nominal shear strength Ω v = 15 = factor of safety for shear F = yield stress A w = area of web Storm Water Runoff Rational Method Runoff Coefficients Categorized by Surface Forested 0059—02 Asphalt 07—095 Brick 07—085 Concrete 08—095 Shingle roof 075—095 Lawns, well drained (sandy soil)Dividend yield ratio shows what percentage of the market price of a share a company annually pays to its stockholders in the form of dividends It is calculated by dividing the annual dividend per share by market value per shareThe ratio is generally expressed in percentage form and is sometimes called dividend yield percentage Since dividend yield ratio is used to measure the relationshipSlenderness Ratio Used for Separation calculator uses Slenderness ratio for separation=((2*(pi^2)*modulus of elasticity)/(Yield stress of steel))^(1/2) to calculate the Slenderness ratio for separation, The Slenderness Ratio Used for Separation formula is defined for demarcating between the elastic member buckling from inelastic member buckling

How Come The Yield Strength Is Greater Than Tensile Strength When Testing A Steel Specimen Quora

Mechanical Properties Of Materials Mechanicalc

Whether an object is stubborn or malleable is decided by the yield strength It is the point at which an object ceases to be elastic and becomes plastic Yield strength helps us choose appropriate materials for the construction based on the requirementYield Strength Definition Stress Strain Graph Stress Strain Graph Explanation Yield Strength Graph What is Yield Strength?Yield ratio definition Yield ratio refers to one of the key performance indicators (KPI) in human resources that shows what percentage of candidates from a specific source was invited for an interview Essentially, yield ratio shows how efficient is the selected recruiting method

Stress Strain Curve Wikipedia

Basic Of Drillpipe Tensile Capacity And Its Calculation Drilling Formulas And Drilling Calculations

A constant required value, imposed by law, standardTensile Yield Strength Unit Conversion Calculator;Stress is also related to strain and the young's modulus, which is a ratio of stress to strain in an object under a certain force denoted by this equation E = σ/ε Stress and strain a linearly proportional when the under elastic behavior When an object breaks or starts to yield this relationship no longer holds The following example

Mechanical Properties Of Materials Mechanicalc

Stress Ratio An Overview Sciencedirect Topics

A constant required value, imposed by law, standardEssentially Poisson's ratio is one measure of a rock's strength that is another critical rock property related to closure stress Poisson's ratio is dimensionless and ranges between 01 and 045 Low Poisson's ratio, such as 01–025, means rocks fracture easier whereas high Poisson's ratio, such as 035–045, indicates the rocks are harderYP ⇒ Yield Point Stress at which there are large increases in strain with little or no increase in stress Among common structural materials, only steel exhibits this type of response σ YS ⇒ Yield Strength The maximum stress that can be applied without exceeding a specified value of permanent strain (typically 2% = 002 in/in)

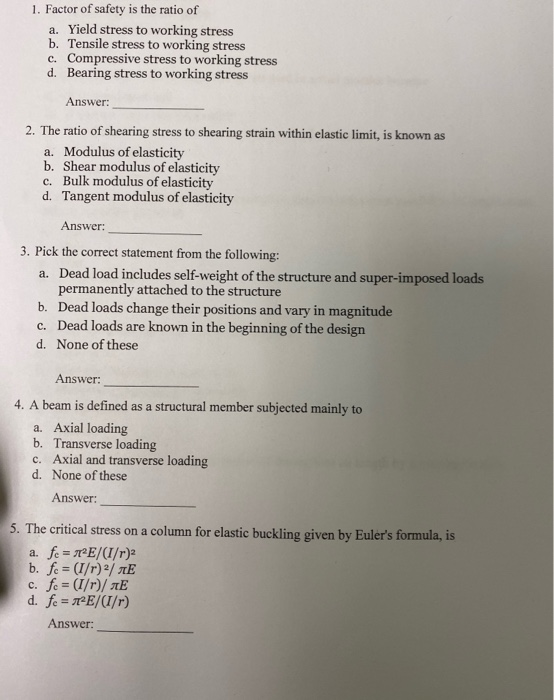

Solved 1 Factor Of Safety Is The Ratio Of A Yield Stres Chegg Com

Minimum Yield Strength An Overview Sciencedirect Topics

When the stress in a specific position becomes superior to the strength of the material, the safety factor ratio becomes inferior to 1, this when there is danger What it tells us basically is that in a specific area of the model, the stress is higher than the strength the material can bearYield point is a point on the stressstrain curve at which there is a sudden increase in strain without a corresponding increase in stress Not all materials have a yield point See accompanying figure at (1) Yield strength, S y, is the maximum stress that can be applied without permanent deformation of the test specimen This is the value ofThe stress value, in pounds per square inch, is the yield strength It is indicated in Figure 5 as Point 3 This method of plotting is done for the purpose of subtracting the elastic strain from the total strain, leaving the predetermined "permanent offset" as a remainder

On Yield Stress Of Compacted Clays Springerlink

Stress Cycle An Overview Sciencedirect Topics

Yield ratios can give you an indepth picture of your hiring process when they're analyzed according to certain criteria For example, imagine that you calculate the gender ratio for new hires You find that percent of your total new hires are women You could perform the same kind of calculation for minoritiesSlenderness Ratio Used for Separation calculator uses Slenderness ratio for separation=((2*(pi^2)*modulus of elasticity)/(Yield stress of steel))^(1/2) to calculate the Slenderness ratio for separation, The Slenderness Ratio Used for Separation formula is defined for demarcating between the elastic member buckling from inelastic member bucklingYIELD STRESS/TENSILE STRESS RATIO RESULTS OF EXPERIMENTAL PROGRAMME British Steel plc 1 INTRODUCTION 11 Concepts of the Yield/Tensile Ratio One of the principal objectives of many modern steel structures is the optimisation of the useful weight by providing an efficient design incorporating high strength steels

Yield Point Yield Point Ratio Offset Yield Zwickroell

What Is The Basic Difference Between Yield Strength And Ultimate Strength For Any Elastic Material Quora

Material 24T4 Aluminum, Yield Strength= psi, Modulus of Elasticity=104E6 psi, Poisson's Ratio=333 Max Bending Stress o V H W t = 393 lbf o K o = 125 Overload Factor, based on light shocks encountered o K v = 110 Dynamic Factor, based on quality and velocity of gears o K s = 1 Size Factor o PYield stress is defined as the stress after which material extension takes place more quickly with no or little increase in load Point (BC) is the yield point on the graph and stress associated with this point is known as yield stress Ultimate Stress Point (D) Ultimate stress point is the maximum strength that material has to bear stressDefine yield stress ratios to specify the rate dependence independently, as described in the procedure below For more information on strain rate dependence, see Ratedependent yield Create a material model as described in described in one of the following sections

Stress Vs Strain Curve Video Khan Academy

Strength At Break Tensile

Shearing stress stress that tends to shear the material acts inTemp (C) Time(Mints)Yield Tensile Ratio 675 12 586 602 097 675 15 575 595 096 725 480 504 095 But the yield and tensile is reducing with the same proportion, hence the ratio is same Please advise what we should do to reduce the ratio

Yield Point An Overview Sciencedirect Topics

Definition Of Balanced Steel Ratio Chegg Com

Yield Strength Definition Examples Stress Strain Graph Faqs

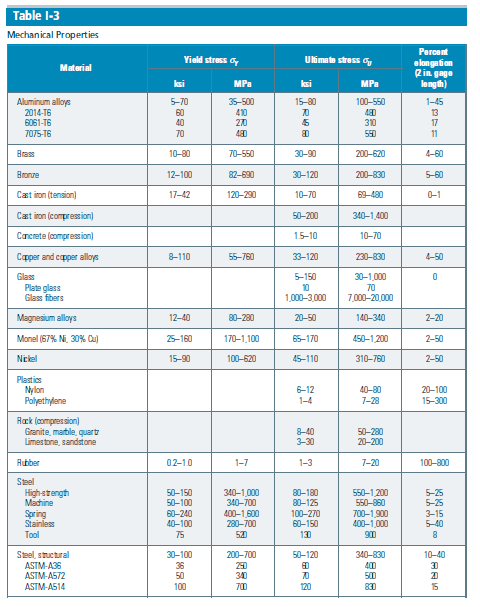

Material Properties

Johnson S Parabolic Formula Wikipedia

Elastic Limit An Overview Sciencedirect Topics

Strength Of Materials Basics And Equations Mechanics Of Materials Engineers Edge

What Is The Ultimate Tensile Strength And Yield Strength Of Mild Steel And Hysd Bar Quora

Yield Strength Strength Mechanics Of Materials Engineers Edge

Estimating Tensile Strength From Yield Or 0 2 Proof Values Twi

Calculate Yield Stress Youtube

Importance Of Yield Strength Plastic Deformation To Civil Engineers

Stress Strain

What S The Difference Between The Elastic Modulus And Kinetic Modulus Machine Design

Solved Using The Information Provided Why Was The Third Chegg Com

Shear Stress Is 0 5 Of Tensile Stress Is It Applicable In All Cases Quora

Stress Strain Curve How To Read The Graph

The Differences Between Stiffness And Strength In Metal

Effects Of Gd Solutes On Hardness And Yield Strength Of Mg Alloys Sciencedirect

What Is Yield Stress Definition Formula Video Lesson Transcript Study Com

Q Tbn And9gcq Lokv6u6biweu7e6sd5mb7neolnaw Dcdbogfctf 8hvcdutp Usqp Cau

Material Properties

Flexural Behavior Of Beams Reinforced With Steel Bars Exceeding The Nominal Yield Strength

Ramberg Osgood Relationship Wikipedia

Shear Yield Strength An Overview Sciencedirect Topics

How To Find Yield Strain Corresponding To 0 2 Offset Yield Stress

Reinforcing Steel Properties Of Shear Panels Fy Yield Strength P Download Table

.jpg)

Yield Stress Calculation Methods

Yield Point Yield Point Ratio Offset Yield Zwickroell

Von Mises Yield Criterion Wikipedia

Critical Resolved Shear Stress Wikipedia

Compression Springs How To Calculate Spring Stress Tokai Spring Industries Inc

Minimum Yield Strength An Overview Sciencedirect Topics

Importance Of Yield Strength Plastic Deformation To Civil Engineers

Stress Strain Curves Of Metallic Materials And Post Necking Strain Hardening Characterization A Review Tu Fatigue Amp Fracture Of Engineering Materials Amp Structures Wiley Online Library

Yield Stress An Overview Sciencedirect Topics

Stress Strain Curve Wikipedia

Engineering Fundamentals Refresh Strength Vs Stiffness Vs Hardness Fictiv

Critical Stress An Overview Sciencedirect Topics

What Is Yield Stress Definition Formula Video Lesson Transcript Study Com

5 Grades 60 And 80 Stress Strain Curves For Astm A615 And 06 Download Scientific Diagram

What Is Yield Stress Definition Formula Video Lesson Transcript Study Com

Indirect Tensile Strength Test Principle And Calculation Of The Itsr Download Scientific Diagram

Stress Ratio An Overview Sciencedirect Topics

Solved The Strength To Weight Ratio Of A Structural Material I Chegg Com

Engarc L Offset Yield Method

What Is The Relation Between Hardness And Tensile Strength Quora

Www Rocscience Com Help Rs3 Pdf Files Theory Constitutive Models Manual 8 Cam Clay And Modified Cam Clay Models Pdf

Yield Engineering Wikipedia

Stress Ratio An Overview Sciencedirect Topics

Yield Strength Of Plastics Basic Principles The Tensile Test And Material Property Table Engineeringclicks

Yield Strength Strength Mechanics Of Materials Engineers Edge

Modulus Of Elasticity Instron

Stress Ratio An Overview Sciencedirect Topics

113 Questions With Answers In Yield Strength Science Topic

Stress Ratio An Overview Sciencedirect Topics

Experimentally Measured Yield Stress For Berea Sandstone Compared With Download Scientific Diagram

Yield And Tensile Strength Engineering Materials Youtube

Q Tbn And9gcqdhkmo7hherjjmwerev9j1zxqfwpmjetj5gvnkildcbtyau41x Usqp Cau

Static Material Properties Of 7075 T651 Download Table

Mechanical Properties Of Materials Mechanicalc

Solved 47 Match These Names To The Numbers A No Load B Chegg Com

Strength Of Materials Basics And Equations

Stress Strain And Young S Modulus

Introduction To Reinforced Concrete Structural Design An Online Course For Engineers And Land Surveyors

Yield Stress An Overview Sciencedirect Topics

Solved Figure Q5 A Show The Critical Stress Versus The S Chegg Com

113 Questions With Answers In Yield Strength Science Topic

What Is Yield Stress Definition Formula Video Lesson Transcript Study Com

Euler S Critical Load Wikipedia

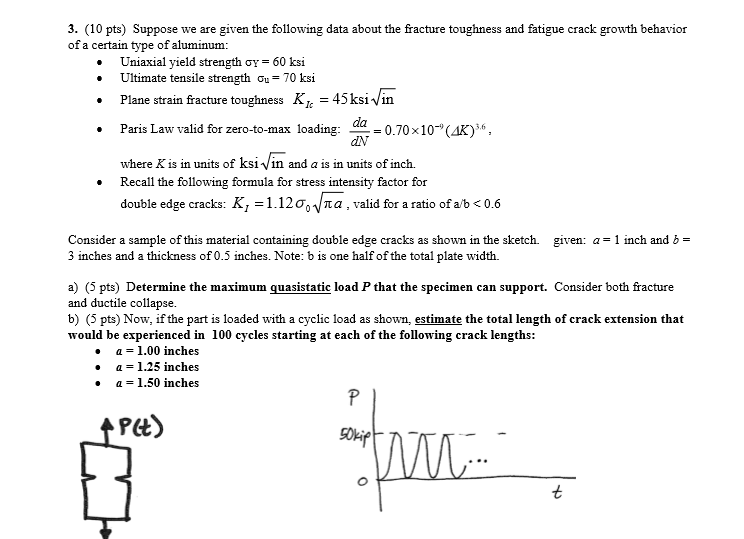

Solved 3 10 Pts Suppose We Are Given The Following Dat Chegg Com

Mechanical Properties Of Materials Mechanicalc

コメント

コメントを投稿